Guide to Testing Concrete Moisture Levels Before Floor Installation

Flooring professionals must drill holes for RH probes.

Imagine spending the time and money to install your customer’s flooring—or your own—only for it to show signs of moisture damage shortly after.

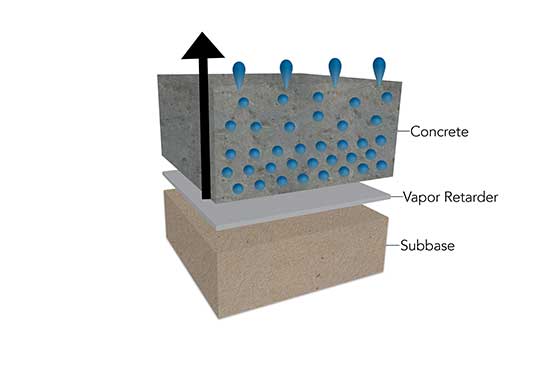

The concrete subfloor can hold excess moisture, which, when released, can damage the flooring material above it.

Fortunately, here at Wagner Meters, we know what it takes to prevent moisture damage in the first place. And that all begins with testing your concrete for excess moisture.

Join us as we explain everything you need to know about concrete moisture testing. We’ll help you understand:

- What concrete moisture is and why it matters

- Concrete moisture testing myths

- The best concrete moisture test

- How to test concrete moisture levels

- How Wagner Meters can help

Let’s get started!

What Is Concrete Moisture, and Why Is It Important?

Concrete moisture is any moisture that exists within a slab of concrete. It’s important to understand these moisture levels because the release of excess moisture can lead to floor damage.

Concrete moisture exists both as bound water and free water.

Bound water is chemically bonded with cement to make the concrete. These chemical bonds trap it within the concrete, meaning it can’t be released.

Free water, on the other hand, can be released from the concrete.

To create finished concrete, a fair amount of water must be added to the concrete mixture. This means there will automatically be excess moisture in the form of free water when the concrete is first poured. Much of this excess moisture will release from the concrete over time as it’s exposed to the surrounding air.

But if you, a floor installer, place flooring over the concrete before it’s had an opportunity to dry, that moisture will be released from the concrete, only to be absorbed by the flooring above.

The more free water the concrete has, the more damage it can cause. When the moisture is released, it could cause the flooring above it to cup, buckle, or grow mold. Concrete subfloors that haven’t dried properly have even been known to cause total flooring failure!

That’s why testing your concrete prior to floor installation is extremely important to ensure it has released enough of this excess moisture.

Concrete Moisture Testing Myths

You have to measure deep within concrete to get accurate RH results because most of its moisture is near the bottom of the slab.

As straightforward as concrete moisture testing can be, there are a lot of misconceptions about what accurate moisture testing involves.

Some people have the misunderstanding that:

Cured concrete is dry concrete

Cured concrete has hardened to a solid material, but that doesn’t necessarily mean it’s dry.

It takes a lot of water to turn a concrete mixture into finished concrete. This inevitably results in excess moisture within the concrete even after it’s hardened. The concrete will release this moisture and become more dry over time.

Old concrete is completely dry

Though your old concrete may have been dry at some point, water intrusion can saturate the concrete, causing it to go over recommended moisture levels.

Some concrete slabs also take longer to dry than others. The composition of the concrete and the environment it’s placed in may cause drying times to vary. So, the slab may still contain excess moisture even when it’s old.

Concrete drying times can be accurately estimated

Some people assume that a concrete slab needs a month to dry for each inch of depth. But this rule of thumb does not acknowledge the fact that different factors—like airflow, humidity, and temperature—can affect the time it takes concrete to dry.

That’s why it’s important to treat each slab of concrete as an individual case. Instead of relying on assumptions, test the moisture levels to get an accurate picture of how the drying process is going.

Surface moisture testing methods are sufficient

Surface testing methods like calcium chloride testing and concrete moisture meters can’t tell you when concrete has reached appropriate moisture levels.

This is because they both measure only the surface of concrete slabs.

They can indicate the presence of moisture, but they can’t give an accurate reading of moisture levels because they’re missing the place where most moisture exists—deep within the slab.

This is where relative humidity (RH) tests come in.

What Is the Best Moisture Test for Concrete Floors?

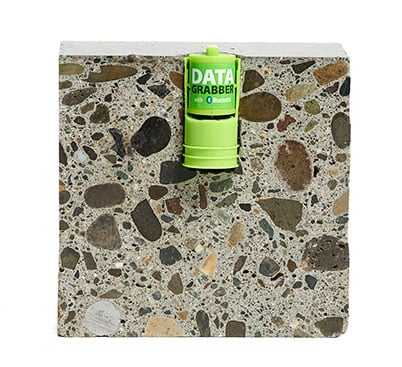

Relative humidity (RH) testing is the best concrete moisture testing method. While concrete moisture meters and calcium chloride tests only measure the surface of concrete, RH tests measure deep within a slab using in situ probes.

These probes allow you, the flooring covering installer, to get a better picture of how much moisture exists in the entire slab.

And the process is straightforward. Read on to learn how to conduct this test.

How to Test Concrete Moisture Levels

The Rapid RH® L6 probes go deep into concrete slabs, helping you get accurate RH results fast!

We’ll break down the moisture testing process into three, straightforward sections:

- Getting ready

- Measuring moisture levels

- Analyzing the results

1. Getting ready

This first step involves preparing yourself, your tools, and the environment.

It’s important to take safety precautions when you’re working with concrete. Wear goggles, knee pads, and a respirator to protect your body from hazards.

Then, gather your tools. You’ll need:

- In situ probes

- A masonry drill

- A wire brush

- A vacuum or vacuum attachment

Make sure your RH sensors are calibrated to ensure the most accurate results—that is, unless you’re using sensors that come with a NIST certificate of calibration like our Rapid RH® probes. These sensors don’t require further calibration for accurate readings.

And finally, be sure the surrounding air and concrete have been at service conditions for 48 hours prior to testing.

2. Measuring moisture levels

To conduct a relative humidity test according to ASTM F2170 standards, perform the following steps:

- Drill holes: Drill three holes for the first 1,000 square feet of concrete you have. After that, drill one hole for each additional 1,000 square feet. If your concrete is drying from the top, you’ll want to drill a hole 40% into the slab. If it’s drying from top and bottom, the hole will need to be drilled 20% into the slab.

- Place probes: Clear the drilled holes of debris. Place the probes according to the probe manufacturer’s instructions. If you’re using Rapid RH, put the Smart Sensors in the holes before capping and sealing them.

- Check probes: You can check the probes after you’ve let them sit in the holes for 24 hours.

This method is preferred over calcium chloride testing, which only measures the surface of the concrete for moisture. ASTM 1869, the standard for calcium chloride testing, even states that it should not be performed on lightweight concrete because the calcium chloride readings can be erratic.

What’s more, the calcium chloride test requires 60–72 hours before results can be gathered—so it takes much longer than RH testing which only requires 24 hours to equilibrate according to ASTM standards.

3. Analyzing the results

After 24 hours, you can analyze your RH readings. These RH readings will help you determine whether your concrete has reached acceptable moisture levels.

You can tell your concrete is ready if the RH is at or below the manufacturer’s requirements for the floor covering. You can find this information on the manufacturer’s website. You’ll want your concrete to have an RH under 75% or whatever level the manufacturer specifies. Many specify 85% or less.

How Can Wagner Meters Help?

Wagner Meters is here to help you with proper moisture testing so you can avoid the costs of flooring failures. Whether you’re a flooring professional or a DIYer, we know you’ll benefit from the advice on our blog and the tools in our shop.

If you’re looking for an accurate and reliable RH testing system, look no further than Rapid RH®. On top of being accurate, our Rapid RH probes:

- Deliver quick results

- Are ASTM compliant

- Cost less than other ASTM-approved testing methods

- Store RH data

- Are easy to use

Download the Rapid RH ASTM F2170 Checklist – Ensure Accurate RH Testing Every Time!

Jason has 20+ years’ experience in sales and sales management in a spectrum of industries and has successfully launched a variety of products to the market, including the original Rapid RH® concrete moisture tests. He currently works with Wagner Meters as our Rapid RH® product sales manager.

Last updated on March 11th, 2025